Distillation: the extraction of essential oils is done through water, water-steam and steam distillation.

The distillation technological equipment includes various capacities and volumes:

• Distillation apparatus

• Shell-and-tube cooler with various cooling surfaces

• Furnace glass

• Florence flask

• Distillate tank

• Cohobation column

• Cube residue (graft) tank

• Rose water tank

• Cold water tank

• Warm water tank

• Distillate mixing tank

• Rose marc draining machine

• Stainless steel pumps

• Stainless steel pipes and fittings - delivery and installation

Extraction: the essential oil extraction is done by means of volatile solvents (hexane, ethanol, etc.).

Technical hexane is the most commonly-used one:

• Extractor (raw material charge)

• Extractor cooler

• Reflux condenser

• Basket for raw materials

• Evaporator

• Evaporator cooler

• Vacuum evaporator

• Vacuum evaporator cooler

• Receiver

• Water separator

• Water separator (horizontal or vertical solvent tank)

• Аngular filter

• Horizontal or vertical solvent tank

• Explosion-proof pumps (ATEX)

• Stainless steel pipes and fittings - delivery and installation

Distillation Apparatus

-tank.jpg)

Cohobation columns with cube residue (graft) tank

Detail info parameters

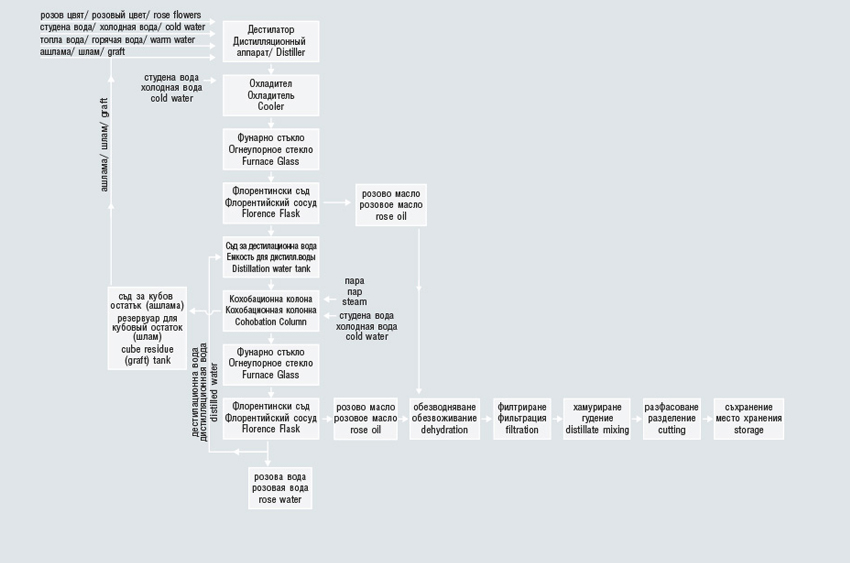

Diagram of the technological process for rose oil production

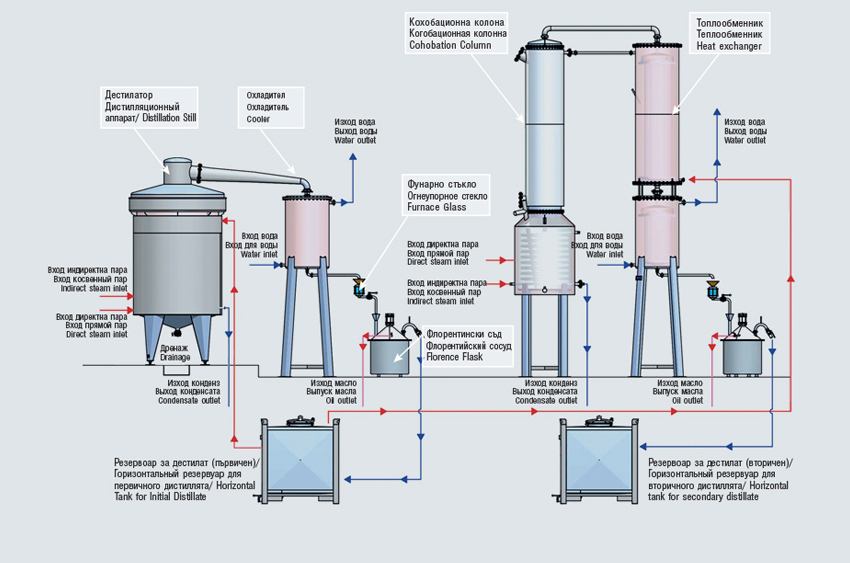

Distiller with heatexchanger

Distillery technological diagram

Florence flask

Florence flask

Furnace glass

Tank

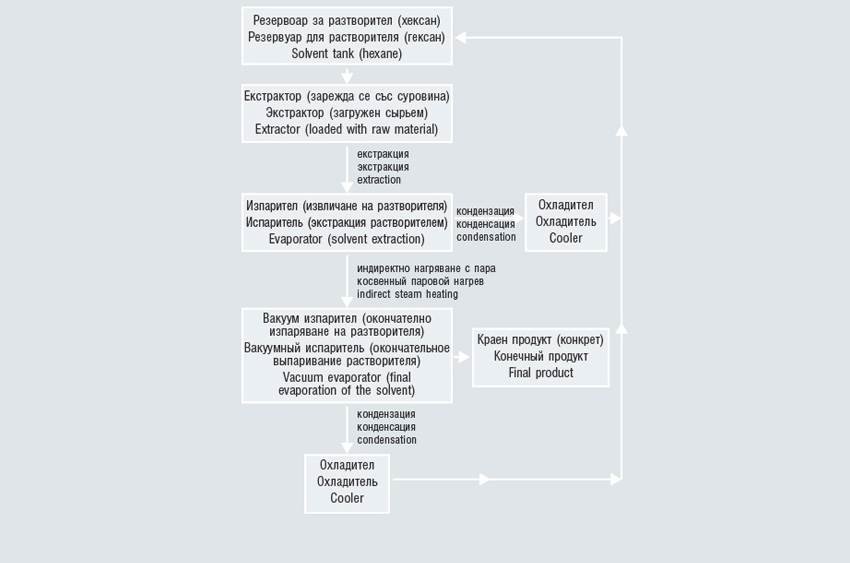

Technological diagram Extraction process

Views Distillery for essential oils

Views Distillery for essential oils

Views Distillery for essential oils

Views Distillery for essential oils

Views Distillery for essential oils

|

6, Vassil Levski Blvd., 6300 Haskovo, Bulgaria |

|

Tel. +359 (0)38 664601 |

|

Fax: +359 (0)38 664604 |

|

e-mail: pim@pimbg.com |