PIM Ltd. designs and produces equipment for bee honey manufacturing, based on a classic technology. The capacity and size of the facilities depend on the specific project of the client and the client's requirements for honey extraction.

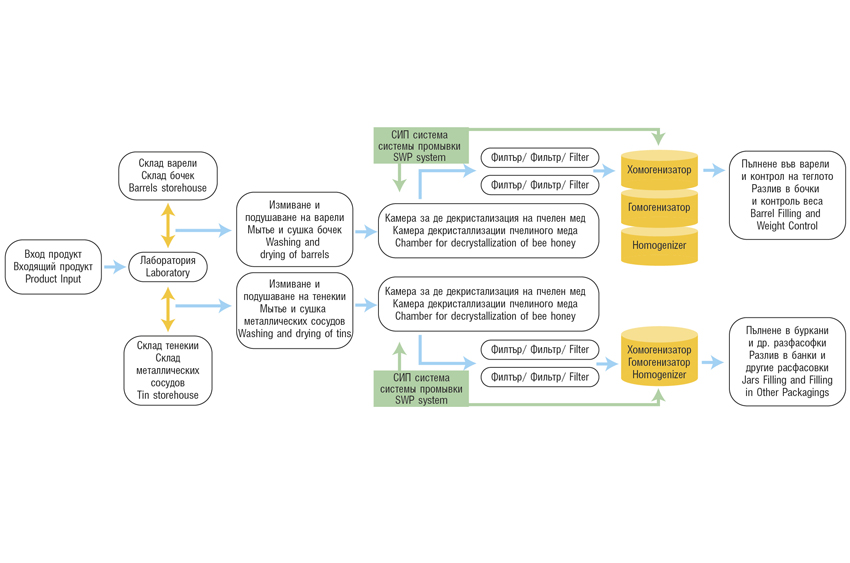

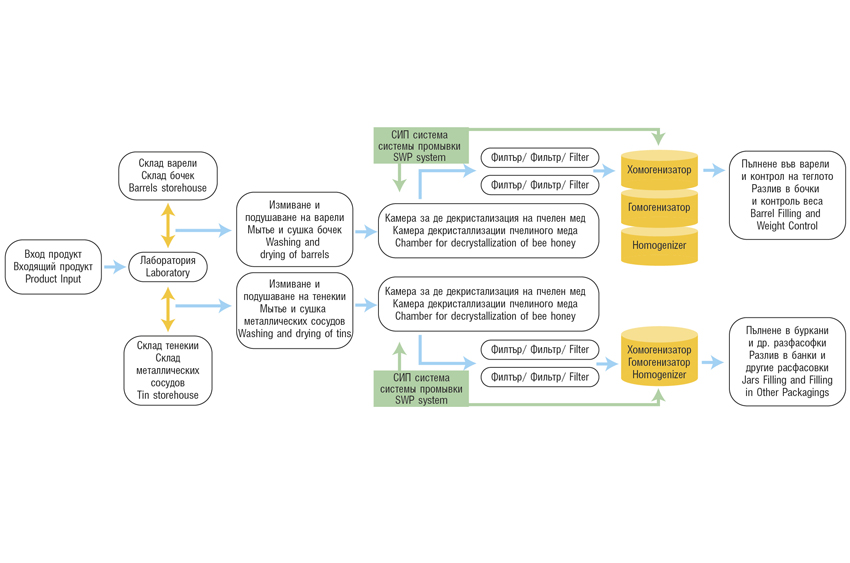

PROCESS - principal equipment:

- Reception room - chemical analysis of a missing raw material and formation of batches depending on the indicators. Thermisation

- Washing and drying of tins, barrels with incoming product - hermetically sealed

- Decrystallization - in thermal chambers (from 1 to 4-6 hours) depending on the temperature of the incoming product and the degree of crystallization. Heat treatment of the honey, filtering (cleaning from small residues of bees, wax, etc.)

- Homogenization - homogenization 4-6 hours depending on the type of honey, through stirring and maintaining of the temperature of the bee honey

- Spilling – filling - in barrels V = 200 litre, weight control - 290 kg

- Systems for an intermediary heat carrier

- Horizontal tank for initial distillate:

- for thermal chambers

- for homogenizers

- for tubing

- SWP system

- for washing of thermal chambers, homogenizers, tubing,

- Tubing:

- by product

- by intermediary heat carrier

- by SWP

The bee honey production equipment ("turnkey") is offered as a comprehensive, fully complete solution:

- Process automation

- Pumps

- Pipelines

- Packaging and transport

- Installation

| GALLERY |

|

-

ПЧЕЛЕН МЕД - Оборудване за производство

-

ПЧЕЛЕН МЕД - Оборудване за производство

-

ПЧЕЛЕН МЕД - Оборудване за производство

-

ПЧЕЛЕН МЕД - Оборудване за производство

-

ПЧЕЛЕН МЕД - Оборудване за производство

-

ПЧЕЛЕН МЕД - Оборудване за производство

-

ПЧЕЛЕН МЕД - Оборудване за производство

-

ПЧЕЛЕН МЕД - Оборудване за производство

-

ПЧЕЛЕН МЕД - Оборудване за производство

-